Billy Todd, owner of 108 Excavating in Flagstaff, Ariz., has been busy. “Flagstaff has grown a lot,” Todd says. “There isn’t any shortage of work, that’s for sure. I’ve been working in dirt since I was a little boy. It’s what I’ve always wanted to do.”

You can’t say Todd is a boy anymore, though. He is the 33-year-old owner of a thriving excavation company. He has roughly 30 employees, a growing equipment fleet, and a growing list of clients in both the commercial and residential markets.

The company name, 108 Excavating, is somewhat of a head scratcher. No, it’s not the company’s postal address. It’s not the model number of Todd’s favorite excavator. The 108 ties back to Todd’s dirt bike racing days. “I raced motocross when I was younger, and 108 was the number on my bike,” Todd says.

Todd says he spent nearly his entire youth in the dirt, either riding dirt bikes or working in his father’s excavation business.

“I was about 5 years old when I first started learning how to run a backhoe,” Todd relates. “Then I worked for my old man all through high school, up until 2015 when I decided to start my own business. My dad was primarily doing residential work. I wanted to expand into the commercial and residential development side of things.”

Versatility helps flex with market changes

Versatility helps flex with market changes

In 108 Excavating’s early years, Todd and a single employee found themselves doing a large amount of work on the Northern Arizona University campus.

“We do a lot of work for Core Construction today,” Todd points out. “It actually started off when I was doing work for the concrete contractor at the time. That’s how I was able to build a relationship with Core’s project managers and superintendents. It wasn’t long after I started my company that Core started giving me work to bid. Soon we were doing work directly for Core, and a lot of it was on the NAU campus.”

Although the campus work has slowed down, it is really what allowed 108 Excavating to springboard to where it is today.

As of mid-June, 108 Excavating had several projects underway. Half were commercial and half were residential development. Being versatile enough to cater to both market segments has always been important to Todd. This philosophy proved invaluable last year.

“When COVID hit last spring, a lot of the commercial work went dormant,” Todd recalls. “We were able to keep things going with residential projects. Now this year, commercial has come back strong while residential has slowed down a bit. One of our recent projects was an elementary school. We did all of the pads, dirt work, utilities and stormwater. We also did all of the paving. The nice thing is, we do a lot of the same types of work for both types of clients. That allows us to go back and forth as needed.”

One thing 108 Excavating does differently in the residential market is offer landscaping services — primarily hardscaping and pavers. It’s a natural fit for the company’s existing equipment and employee skillset. Plus, it helps fulfill a growing need in the market.

Keys to becoming the ‘company of choice’

Keys to becoming the ‘company of choice’

Billy Todd grew up working in dirt, but he doesn’t spend nearly as much time there today. As his company has grown over the past six years, Todd has had to spend more time in his role as “owner” and less time as “operator.” He misses the sanctuary of an excavator cab, but also realizes where his time is best spent.

“I handle all of the bidding for the company, which is what I primarily spend my time on,” Todd says. “I also like to go out and check on our jobs to make sure the finished quality is there and we’re not compromising anywhere. We have to make sure our standards are up.”

Todd is quick to point out that it’s a huge plus to have employees he can count on to help operate the business. Finding employees has definitely been a challenge, but Todd says he has been lucky.

“We have a pretty young crew, and all of us have grown up learning this together,” Todd says. “I worked alongside several of my employees when I was still working for my dad. My guys are really sharp. I haven’t had much luck bringing guys in who already have a lot of construction experience. Our company does things differently than many other companies. So I like to train my guys to our standard. I don’t personally do much of the training anymore; I lean on my key foremen. I pair an employee with a foreman who I think they’ll get along with the best. That has been working very well.”

An example of something 108 Excavating does differently relates to material.

“We process all of our own material,” Todd points out. “We’ll demo concrete or asphalt, but we don’t take it to the dump site in town. We actually keep it all and crush it, and then reuse it. We have very little spoil aside from some of the organics we can’t really do anything with. But we try to recycle as much as we can. People in Flagstaff like to see that because it’s the responsible thing to do.”

Another thing that could be viewed as “different” is the fact that Todd implores his employees to never skimp on anything. Even in a hot market where there’s no shortage of work, it’s all about exceeding the customer’s expectation in order to become what Todd calls “the company of choice” in the Flagstaff area.

“We’ve only been in business for six years or so, but we’ve been doing this a long time,” Todd says. “We know what customers expect, so we like to do certain thing before they have to ask us to do them. We want to make sure that whoever we’re working for is not worried about having to watch over what we’re doing.”

Case in point: compaction tests. Todd says a lot of general contractors have their own expectations. “We learn what those expectations are. Then we can get ahead of it and schedule tests on our own so they don’t have to worry about it,” Todd explains.

A lifetime of loving heavy equipment

A lifetime of loving heavy equipment

The past six years have been a whirlwind for Billy Todd. His duties as company owner have had to change, but his passion for “working in dirt” hasn’t waned a bit. Neither has his loyalty to CASE Construction Equipment.

Currently, 108 Excavating’s equipment includes four wheel loaders, four large excavators, four mini-excavators, three backhoes, two skid steers, a dozer with GPS, an impact crusher and a scalping screen. “Everything we own is a CASE, aside from our Rubble Master crusher and scalping screen,” Todd points out.

That first backhoe Todd learned to operate in kindergarten was a CASE. He has been loyal to the brand ever since.

“My dad was always really loyal to CASE, and they’ve never done us wrong,” Todd says. “Up here in the Rocky Mountains, the backhoes in particular are great because they are the most nimble machines I’ve ever run.”

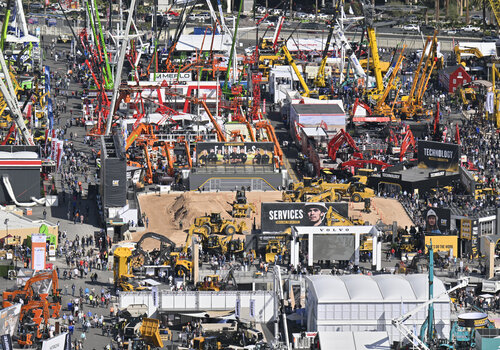

Rest assured, the next time Todd needs a new piece of equipment, there’s a good chance he’ll purchase something with the CASE decal on it. That said, he still sees a lot of value in attending CONEXPO-CON/AGG in Las Vegas. The first show he attended was last year (2020). He brought 10 employees with him.

“I had always wanted to go to the show, but just never had the chance,” Todd says. “We made a commitment to attend last year. I wanted some of my longer-term employees to experience it, too. We want for three days. I wanted my guys to see all of the new technologies coming out. I wanted to get them thinking about things that could help our company in the future. The show was a good learning experience for all of us. It also helped reinforce how important my employees are to the company and how much I value their opinion.”

Join more than 50,000 industry peers who receive construction industry news and trends each week. Subscribe to CONEXPO-CON/AGG 365.