Excavators are indispensable workhorses on construction sites, but it's often their attachments that truly unleash their potential. Today's attachments significantly enhance excavator capabilities, enabling contractors to execute jobs more efficiently, safely and cost-effectively. Here’s a look at the top excavator attachments – form the tried and true to the latest and greatest – that are transforming construction sites today.

HYDRAULIC THUMBS

Hydraulic thumbs transform excavators into precise material handlers, capable of gripping irregular objects securely. Ideal for demolition, site clearing and recycling, they provide improved safety by reducing the manual handling of debris.

Example: Caterpillar’s Hydraulic Thumb features adjustable rotation and secure gripping, ensuring contractors can safely maneuver large boulders, timber or demolition debris.

Cost Savings & Benefits:

- Minimizes labor costs by reducing manual debris handling.

- Improves safety and efficiency, shortening job timelines.

Considerations:

- Requires regular hydraulic system maintenance to avoid downtime.

TILTROTATORS

Tiltrotators provide unmatched precision by allowing excavator buckets and attachments to tilt and rotate 360 degrees continuously. This capability significantly improves flexibility in tight or challenging spaces, perfect for urban or constrained job sites.

Example: The Engcon EC-Oil automatic quick coupler system allows operators to switch attachments quickly, with advanced tiltrotator functionality enhancing precision during trenching or grading operations.

Cost Savings & Benefits:

- Reduces the need for repositioning equipment frequently.

- Enhances productivity, accuracy, and versatility, reducing overall project time.

Considerations:

- Higher upfront investment, offset by considerable productivity gains.

CRUSHER BUCKETS

Crusher buckets enable excavators to crush rock, concrete and asphalt directly on-site, eliminating costly off-site disposal and transportation expenses.

Example: MB Crusher’s BF90.3 bucket can crush materials from demolition or excavation sites, directly repurposing debris into usable aggregates for backfill, road base or drainage material.

Cost Savings & Benefits:

- Cuts transportation and landfill disposal costs dramatically.

- Generates reusable aggregate, reducing the need for purchasing new materials.

Considerations:

- Requires operators with specific training to optimize crushing efficiency and bucket lifespan.

HYDRAULIC BREAKERS

Hydraulic breakers are essential for demolition, roadwork, trenching and rock excavation. Advanced breaker designs for compact evacuators now offer power and efficiency with minimal noise, ideal for urban and indoor projects.

Example: Volvo’s new hydraulic breakers, HB01 and HB02, offer consistent impact frequency and power with low noise.

Cost Savings & Benefits:

- Enhanced efficiency reduces operational and fuel costs.

- Lower noise and vibration improve operator comfort and safety.

Considerations:

- Regular maintenance is crucial for consistent performance and avoiding costly downtime.

SCREENING BUCKETS

Screening buckets efficiently separate materials directly on-site, ideal for sorting topsoil, compost and demolition debris, improving resource management and job site cleanliness.

Example: ALLU has a wide variety of screening buckets that utilize innovative drum designs to handle multiple material types efficiently, allowing rapid transitions between screening jobs.

Cost Savings & Benefits:

- Reduces landfill fees by recycling materials on-site.

- Decreases the need for secondary equipment, lowering operational expenses.

Considerations:

- Optimal use requires understanding of screen sizes and material compatibility.

GRAPPLES

Grapples increase excavator versatility for handling bulky materials, from tree limbs to demolition scrap. Advanced grapple systems now include integrated rotation and robust gripping mechanisms, ideal for landscaping, demolition and recycling tasks.

Example: Rotobec has unique attachments that can be designed to fit different hydraulics on machines. This provide both versatility and precise gripping, enhancing productivity in everything from land clearing to demolition.

Cost Savings & Benefits:

- Improves handling efficiency, minimizing labor hours.

- Enhances safety by reducing manual handling.

Considerations:

- Ensuring proper sizing and weight compatibility with excavators to maintain stability.

COMPACTOR ATTACHMENTS

Compactor attachments efficiently compact soil or aggregate in trenches, foundations or backfilled areas, ensuring stable groundwork.

Example: John Deere arm-mounted plate compactors deliver consistent compaction with minimal operator fatigue, reducing both the number of crew needed and time spent on repetitive compaction tasks.

Cost Savings & Benefits:

- Streamlines compaction processes, significantly cutting project timelines.

- Reduces need for manual compaction or additional equipment.

Considerations:

- Periodic checks on hydraulic connections and compaction efficiency to avoid operational delays.

FINAL THOUGHTS

Advanced excavator attachments can significantly boost operational efficiency, cost-effectiveness and site safety. By selecting attachments tailored to project-specific tasks, contractors can maximize productivity and profitability, transforming excavators from basic machines into versatile, powerful tools integral to successful job site operations.

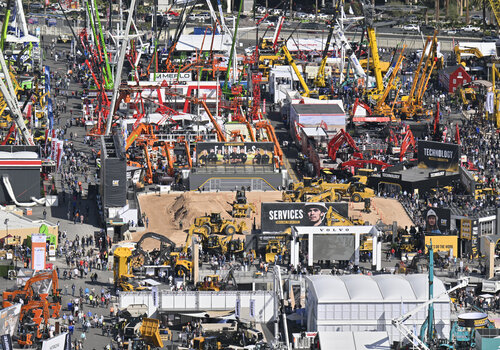

Photo credit: SHUTTERSTOCK.COM/VADIM RATNIKOV