It pays to adhere to safe practices for haul truck loading.

Indeed, injuries from dump trucks led to the deaths of 809 construction and extraction workers from 2011 to 2020, according to the National Institute for Occupational Safety and Health.

“Those operating dump trucks or working nearby are at risk of multiple hazards including struck-by, tip-over from loss of vehicle control, crushing, electrical and falls,” NIOSH writes.

Haul Truck Loading TIPS FROM THE PROS

Two articulated dump truck manufacturers share their best practices in safely loading trucks, followed by NIOSH guidance.

Colton Kreber is product marketing manager at John Deere, who is based in Ames, Iowa. Kreber suggests:

- Always conduct a thorough walkaround around your equipment at the beginning of your shift. Performing daily walkarounds is an important way to ensure the machine stays ready for the tasks at hand. This also includes checking your articulated dump truck’s fluid and battery levels daily to keep performance high and operations running smoothly.

- Operators should familiarize themselves with the key technology features on their equipment to maximize performance and reduce downtime. There are a variety of owner and operator settings that can help ease operation and increase jobsite safety. For John Deere articulated dump trucks, these onboard features include rollover protection, downhill dump protection, frame protection, hill hold, shuttle shifting and descent control.

Jobsites often present unpredictable factors and conditions, and the John Deere advanced vision system offers a customized approach to each jobsite. It adds additional cameras that provide dynamic panning capabilities that automatically pan when in reverse to maximize visibility, always ensuring another layer of protection.

Tyler Smith, product manager — articulated haulers, Volvo Construction Equipment North American based in Shippensburg, Penn., suggests:

- Consider truck bed and tailgate features that will support safe and efficient loading. For example, an overhung tailgate is popular, but if you’re hauling large rocks and worried about them getting stuck in the tailgate, an underhung version might be better for maximum payload.

- The most efficient way to load a truck is side loading. You’ll waste a lot less time, fuel and money compared to backing in and maneuvering your trucks, and less machine movement means a safer site.

- Make sure your excavator operator puts good, heaped loads in the truck and utilizes the bed as much as possible. It’s best to evenly distribute the load across the truck bed to prevent tipping.

- Many OEMs offer technology that can further support safety. For example, on-board weighing helps the operator avoid under- or over-loading the truck. This is a valuable feature that helps you achieve the best cost per ton and work as efficiently as possible.

A few more safety-boosting options that my company offers are hill assist, downhill speed control and a dump support system. Hill assist holds the hauler in place when working on slopes of 10 percent or greater without needing to engage the parking brake.

Downhill speed control is exactly like it sounds: automatically maintaining a set speed when driving downhill. And the dump support system has two helpful settings: one that alerts the operator if they are exceeding the side tilt limit, and one that prevents the bed from raising if the truck is tilted too far.

Remember that safety is ultimately the operator’s responsibility. Investing in proper training through your dealer or OEM is never a waste.

NIOSH GUIDANCE

NIOSH provides guidance to help employers and workers recognize and avoid common hazards to prevent dump truck-related injuries and deaths at construction sites. Recommendations include:

- Prepare and plan ahead by developing a written safety program specific to haul trucks; inspecting the work area; providing staging areas to load the truck; creating internal traffic control plans; minimizing ground workers and following applicable Occupational Safety and Health Administration regulations.

- Consider installing new technologies on trucks, such as cameras, electronic signaling devices or sensors to reduce hazards. These can include devices to warn drivers of workers on foot in the immediate work area; back-up and proximity cameras with a video display for the driver to see their surroundings; proximity detection alarms for ground workers who must be in the work zone; and body-up indicators or electronic sensors to alert drivers that a dump body is in the raised position.

- Train drivers to recognize and prevent hazards related to operating dump trucks. Topics should include internal traffic control plans and standard operating procedures for entering and exiting the work zone; determining a safe distance from overhead hazards particularly electrical lines; emergency procedures if a truck strikes an electrical line and how to safely exit a truck contacting live lines; recognizing and respecting barriers that indicate unauthorized entry; steps to take when tarping and untarping the truck bed and when getting on and off equipment; and sources of instability leading to dump truck tip-overs including.

- Train ground workers on hazards of working near operating dump trucks such as how to avoid being in a blind spot; how to avoid communication difficulties between dump truck drivers and other workers; and recognizing the potential for dump trucks to move unexpectedly.

NIOSH also details best practices to prevent struck-by hazards including back-over incidents; tip-overs from loss of vehicle control; crushing hazards including caught-between hazards; electrical hazards; and falls from dump truck cab or dump bed.

“Employers, contractors and supervisors should take the lead in using these recommendations to help prevent dump truck-related deaths, injuries and close calls,” NIOSH writes.

Ready to take the next step to ensure safety on your job site? Share this article with a colleague, and don’t forget to check out these articles: Think Safety Today and Always, Says AEM Safety Materials in Support of National Safety Month and Build a Culture of Safety This Summer.

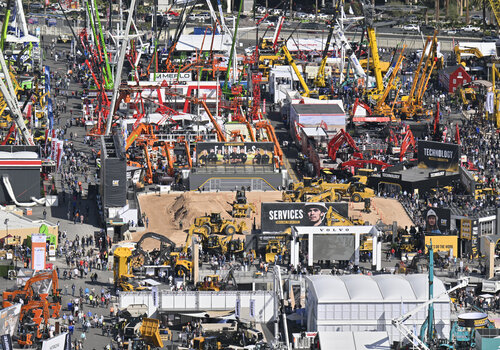

Photo courtesy of John Deere