Joining Taylor on this episode is one of the finalists for the Global Operator Challenge and CEO of Schiedeck Construction, John Schiedeck. John’s been in the construction industry for almost seventeen years and has worked as an owner-operator for the last six. He opens the episode with an overview of his history in the job, from growing up around the industry to racking up the hours with his blade before finally striking out on his own (with help from his wife!). Then, he speaks about some of the challenges involved in being an owner-operator and what sets him apart from his competitors, including his perfectionist tendencies and willingness to take calculated risks. And John also discusses some of the other machinery he owns and the projects he’s currently working on, including some “pretty oddball stuff” for Elon Musk’s companies.

Next, Taylor asks about John’s success in operator challenges, with a new bout coming up on the first day of CONEXPO-CON/AGG. John admits that he didn’t initially want to sign up but was convinced by scores of messages from his social media followers, only to find that his years of experience had given him the skills to win, before sharing some stories of how he developed those skills. He and Taylor then discuss whether being born into the industry and having it in your blood makes you a better operator, as well as their pride in passing their skills down to their kids. John then gives his opinion on GPS and technology on the job site, including his experience with Trimble, how GPS is a valuable tool in the hands of a skilled operator, and the changes he’s seen in technology over his career. And finally, John closes the show by sharing what he’s looking forward to at the CONEXPO show coming up in March, including the chance to get a look at the new technology and machinery being showcased.

Topics:

- The challenges of being an owner-operator

- Working large-scale, big-name jobs

- Operator challenges and having skill in your blood

- The benefits of GPS and technology on the job site

- What John’s looking forward to at CONEXPO-CON/AGG

Watch now:

Listen now:

Listen on your favorite app: Apple Podcasts | Spotify | YouTube

Subscribe to the CONEXPO-CON/AGG YouTube channel to be notified of new episodes.

Join more than 54,700 industry peers who receive construction industry news and trends each week. Subscribe to CONEXPO-CON/AGG 365.

Episode transcript:

Taylor White: Welcome back, everybody, to the CONEXPO-CON/AGG Podcast, brought to you by our good friends over at Komatsu. Cannot wait to see what they have in store for us at this year's CONEXPO show in March. Today I have with me the world's best operator––we're going to go ahead and label him––he's like, "Don't say that." John Schiedeck from Schiedeck Construction, all the way from Central Texas. So thanks for being on the show, John.

John Schiedeck: Thanks for the invite.

Taylor White: Yeah. No, man. Whenever I saw your work at the Cat Global Operator’s Challenge, I was like, "Well, this is somebody who I want to have on." And then I followed you on Instagram and saw that you have a lot of stuff kind of going on. And rather than ask you over social media, I kind of wanted to just get on here and have a good opportunity to chat about you and what you have going on. So I'd like to know a little bit about yourself––like what you have going on. Do you own a business? Do you just run machinery? What do you got?

John Schiedeck: Yeah, I own my own 140M blade and did a lot of owner-operator type work with that. And when I moved here to Texas, I started picking up a lot of my own work. So I'm kind of leaving the seat, per se, and going out and branching out, trying to get my own work and go that route.

Taylor White: Nice. So how long have you done this? Have you always just done grader work?

John Schiedeck: No, I've been in the construction industry for almost 17 years, and I've done pretty much everything topside. I'm not very well versed in underground side. I've done some of it, but more on the finish grading type end of the work. But I've been running blade for myself probably six years now, owning my own blade, and worked for a company before as a utility hand running everything they had, mostly blade for them, for probably five years for them.

Taylor White: I want to know what got you into doing your own thing. But first of all, like, when you say 17 years, what got you into the industry as a whole?

John Schiedeck: It's kind of a family venture. I'm third generation in the seat. My grandparents moved here from Germany after World War II. And when my grandpa moved to California, he ended up starting a– He had seen a need for doing septics and that sort of thing in the area. And so he bought a backhoe and duck truck and then moved over to getting my dad involved, and my dad took it a step further. And then in 2008, when the recession hit, my dad got out of it and kind of branched out to doing more fabricating-type work. Yeah. And I took over the earth's moving side.

Taylor White: Oh, wow. Nice. So that's pretty cool. Your grandfather started doing some septics and stuff. That's kind of what we do up here. That's pretty interesting, just with the backhoe and stuff like that.

John Schiedeck: 1979, I think, is when he started.

Taylor White: Wow, that's incredible. So growing up then, that kind of obviously got you into it being in and around the industry. What aspects of it were you like, "Okay, well, this is what I'm going to do?" Or is it just because that's what family did? That's the path that I'm going to take.

John Schiedeck: I think I was in the seat. I couldn't even sit in it., just reaching the pedal, standing against the seat, and I knew that's what I wanted to do from day one. Everything I've set out to do. When you're a kid, everyone asks you, "What do you want to do when you grow up?" And my three answers were, "Drive trains, fly planes and drive tractors." And I've done all three.

Taylor White: That's pretty neat. So you can fly planes?

John Schiedeck: I've flown before. I'm not a licensed pilot yet. I'm waiting for that opportunity to come.

Taylor White: That's awesome. Yeah, that'd be something that I'd like to try, too. There’s something about being up there, the freedom of it. Much like driving a grader, right?

John Schiedeck: Yeah, I contribute a lot. I talked with the pilot for a while and running GPS and having that bubble in your butt when you run machines. A lot of it. He said a lot of blade hands that he's known make really good pilots.

Taylor White: That's cool. That's really neat. So what got you into doing– You did utility work, but then what got you into doing graders and stuff like that?

John Schiedeck: It all started with a water truck, actually. I worked for a company in the Bay Area in California, and we couldn't find any water trucks. And so I ended up driving down to LA; I bought just a little Bob Till Ford L800, and I built my own truck. I maxed out my credit card, maxed out my savings, and put the whole thing together in my dad's shop, you know, and the thing paid for itself in the first month. And that kind of escalated to buying a mini excavator. And I was renting all these to the company I was working for. They were really good to me.

And so I ended up– We had five motor graders on rent at the time. And I'm like, "Man, I wonder what it would take to buy a blade." And so I started looking into it, and unfortunately, we had to part ways. Conflict of interest, I guess. And I was stuck with a motor grader, so I made it work. Just started calling all the big-name contractors around and seeing if they needed some help on a blade, and they started hiring me, and it went from there. My blade, I bought––let's see, it had 1100 hours on it––and I bought it in 2017, and I'm at 8000 hours on it now. So I put some hours on it in those few short years.

Taylor White: And so you're an owner-operator, then?

John Schiedeck: Yeah, pretty much.

Taylor White: What are some challenges? Being an owner-operator, I mean, like, you're renting it, you’re the one that's doing it, so do you have help on the back end doing the invoicing and the books and stuff like that, or you’re just you're it?

John Schiedeck: No, my wife helps me a lot with the books. She does all the invoicing; she does all the insurance stuff. And when I was in California, we were union so she would handle all that stuff, and that helped a lot. That way, I could go to work and focus on the task at hand.

Taylor White: Nice. There's something to be said about kind of what you just said before, that those you maxed out the credit cards and your savings and you went all in. You say that super quick, but I mean, that's a huge life decision. I mean, that is something that not a lot of people do take that amount of risk, right?

John Schiedeck: Yeah.

Taylor White: What was the thought process behind that? Was it daunting? Was it scary?

John Schiedeck: For me? I knew it would work. I knew it would. My wife, on the other hand, she wouldn't talk to me. She didn't want nothing to do with any of it. And then, after it paid for itself, she realized, okay, she trusts me. With the water truck, she had a hard time with me doing that. And when I bought the excavator, she had a little hard time with that. And then when I bought the blade, I mean, it was over $400,000, and she didn't even bat an eye because she knew it was going to work at that time.

Taylor White: That's good. So basically, you believed in yourself, and you're like, “Yeah, no matter what, I can make this happen.”

John Schiedeck: Yeah. I think it's just a matter of being stubborn to a point. You got to make it work.

Taylor White: Yeah. So where did the skill come into, then? Obviously, being an owner-operator, you're doing it like you said; you bought it with 1100, you got 8000 hours on it now. That's a lot of hours. What sets you apart from other operators? What do you think it is? Obviously, when you're a good operator– If I'm in the bulldozer, I always say– I have a good eye for grade. I can tell just by looking at something. A good operator can tell just by looking at something or the feeling, the way they're feeling of, “Okay, my front is dipping a bit right now,” at least on the dozer, like, “Okay, I went down a bit here. I'm going to feel it when I'm backing up, so I got to lift here.” You kind of know. What is it with you that kind of sets you apart? Do you always have an eye for grade or perfection?

John Schiedeck: I think that's it. I was telling you about my grandpa who immigrated here from Germany, so he's got a really big– He passed away, but had a big artistic side and did oil paintings, and he's got paintings all around the world. And I think his artistic side kind of transferred down to me, and this is my artistic side. I mean, I am a perfectionist, and I have to tell myself, don't worry about it. It looks good, but in my mind, it's never good enough.

Taylor White: You have to be a bit of a perfectionist with stuff like this, and being able to tell yourself, like, “No, that's not just good enough.” That attitude of operators like, “Well, that's good enough.” Especially when you're an owner-operator, that's completely different. Right? Because your work is your reputation, and your reputation is if you get hired or not. So obviously, if you've done that many hours, you've managed to keep yourself busy, which means that you do good work. So you do really good work, and you become that greater operator that people are like, “Well, John, he's really good at this.” Well, then, you're probably going to have work lined up for a while because people are going to want you on their job sites.

John Schiedeck: Yeah. That's how it ended up working out with Texas. I wanted to move to Texas for quite a while, just never really had the opportunity to. And a good friend and client of mine in California had bought 50 acres here in Texas down by San Antonio. And he asked me because we were rained out, we couldn't do any work at the time in wintertime in California; he asked if I'd be interested in going out to his place that he had bought and doing a driveway and house pad and all that for him. And he moved all my equipment out here to do the work. And through social media and Instagram, actually, a really good friend of mine found out I was here, and he's a big shot at one of the local contractors here and found out I was here and said, you're not leaving. And I never left. I told my wife, “You got three weeks. Pack the house up in the horse trailer, and let's go. And that's what happened. That's worked out ever since. But all through reputation and social media and people seeing what I do.

Taylor White: Wow. You’re an all-in kind of guy.

John Schiedeck: Yeah, to a fault.

Taylor White: Yeah, took the risk, maxed everything out, and then moved the family out.

John Schiedeck: Yeah.

Taylor White: That's a big decision.

John Schiedeck: Yeah, a lot of it is faith, I think, too. Having a good relationship with God contribute a lot of it.

Taylor White: Yeah. No, 100%. There's always something playing there 100%. But you have some pictures of some skid-steers, and I saw a story; it was a skid-steer with– It looked like the XE with the cooling package on top. So do you have other machinery as well?

John Schiedeck: Yes, I got that skid-steer, 299D3. I got the forestry package on it. So I got a mulcher and brush hog and bunch of other attachments that would go with it. I got a 615 Scraper, and then between my dad and I, we got a 359 Peterbilt with an end up and a 379 Peterbilt 4000-gallon water truck.

Taylor White: Nice. Yeah, that's pretty impressive. So do you run all those things then?

John Schiedeck: It's actually my dad, my brother, and I; we all do it together. We're at the point right now with work where we need an extra hand; that's growing too fast already. So I don't know when that's going to happen, but it will happen here pretty soon, I think.

Taylor White: Wow. When you say there's so much work ahead and stuff like that, what do you think about the way everything's going on in the news right now when people are talking about recession or slow down or stuff like that? Are you seeing any signs of that?

John Schiedeck: I mean, it's slowing down a little bit here, but I'm kind of watching all the big dogs and bigger guys out there, and they're still going at it. So I'm not seeing too much of a slowdown in here. I think Texas is going to be kind of isolated from it just because of how many people are moving here, and I mean, I'm one of them,

Taylor White: Especially Texas.

John Schiedeck: Yeah. So I think they're going to be a little isolated from it. Yeah, I hope and pray.

Taylor White: The job sites that you guys are on, is it like for residential developments and like roads, or are you doing pads for commercial buildings, or what kind of construction is it?

John Schiedeck: We're doing right now some big apartment complex pads, and then we got a couple of little commercial jobs. I actually do a lot of work for some of Elon Musk's companies that are here, and so I picked some of that up. They keep me pretty busy doing oddball stuff.

Taylor White: That's pretty cool.

John Schiedeck: Yeah, we did a big turn lane off one of the main highways out here for one of their facilities because they're blocking all the traffic with their deliveries coming in. So did that. Yeah, they're keeping us pretty busy. It's pretty nice.

Taylor White: Well, that's pretty cool. You don't hear that too often. That's pretty neat. What's it like? What's the word like whenever he started moving in town? He's obviously creating work and jobs for people.

John Schiedeck: Oh, yeah. He's got the boring company which is his tunneling company. And then right across the street at SpaceX, and then probably 20 minutes away, is Tesla, the huge Gigafactory he just built.

Taylor White: You're close to that. Have you seen that in person?

John Schiedeck: Yeah, I drive by it all the time.

Taylor White: Is it pretty incredible?

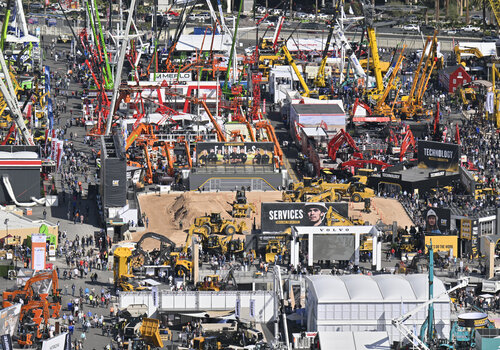

John Schiedeck: Yeah, it's probably a mile long just driving. It's huge. And then we got Samsung; they're doing a huge microchip plant just north of us in Taylor, Texas. They're actually right next to one of the jobs I'm doing for those apartment pads, and when you look– We're right next to them, maybe a quarter mile away, and we counted 130 cranes out there at one time, and that was just what we could see on the skyline. When you drive by, they got a lot smaller cranes in between in the mix, and it looks like CONEXPO. The skyline of all the cranes of CONEXPO, it looks just like that. It's crazy.

Taylor White: Wow. Those scales of those jobs, that's something that I don't see here. I think there may be— I don't even know in Canada if they build stuff like that. That's so intriguing to me. Like hearing that, it's so interesting. It's so unique. Job sites that big like the Gigafactory, seeing that when it was under construction, I mean just the amount of dirt that was moved and machinery that was there and then the concrete, that's pretty incredible.

John Schiedeck: Yeah. Well, the Samsung plant, I have been told, I can't confirm it, but I've been told that it can fit three of the Tesla Gigafactories inside it. That's how big it is. And when you're out there looking at it, it's pretty much connecting two cities together. It's astronomical, the size of it.

Taylor White: Wow. And that creates a lot of work for people.

John Schiedeck: Oh yeah. That town of Taylor is exploding right now with housing. That's insane.

Taylor White: That's crazy.

John Schiedeck: That's another reason why I don't think it's really going to slow down too much, at least for a while, because you see all these big corporations coming here, and they're going to have to have people working.

Taylor White: Yeah. I think that that's kind of important during a recession too. If there ever is or talk of one, it helps kind of location where you are. I always say here in Ottawa; we're in a good location here in Canada because we're the nation's capital. This is where parliament is. So about 70% of our population is federal workers. So they're still always kind of spending money regardless of recession because they don't really lose their jobs. But in a case like yours, no matter what, they're building these factories. No matter what, they need people to work there, so they're going to build the communities to support the workers. And so it kind of sounds like you're in a good position for that.

John Schiedeck: I think so. I just heard Caterpillar’s moving their headquarters here to Texas as well to Dallas, so that's 3 hours from us. But still another big corporation moving down here.

Taylor White: What is it with Texas?

John Schiedeck: I don't know. They're very friendly on tax laws, I bet, for all these big places.

Taylor White: Yeah, I heard that. I heard that they're good on taxes there.

John Schiedeck: Yeah, I love it here. It's amazing here. Leaving a place like California and then coming here, you don’t realize–

Taylor White: A complete opposite.

John Schiedeck: Yeah. You don't realize the freedoms that you had taken away in California until you come to a place like this.

Taylor White: Yeah, 100%.

John Schiedeck: Yeah. It's just free.

Taylor White: Yeah, for sure. So I want to talk about your operator challenge. So Cat puts on a heavy equipment operator’s challenge every year, right?

John Schiedeck: Every three years.

Taylor White: Every three years. Okay. Like on Expo, how did the process go for that? Did you submit yourself for it? How did that kind of come about?

John Schiedeck: Yes, I ended up signing up myself for it. I wasn't going to, but with my social media following, everybody kept messaging me. I probably had 60 people message me, “Dude, you got to sign up. You got to sign up.” And, “Ah, I don't really want to.” And they just kept hounding me, so I ended up doing it and won the first two in Texas and went to the regionals in North Carolina and won that one, and now on to Vegas.

Taylor White: So when is it in Vegas?

John Schiedeck: It's actually the day of my anniversary, March 14.

Taylor White: Wow. First day of CONEXPO. First or second day of CONEXPO. No way.

John Schiedeck: I think it's the first. Yeah.

Taylor White: Wow.

John Schiedeck: I took my wife to CONEXPO three years ago, and I took her to a tractor show for her anniversary. And then now we're going back again, so now I got to win it for her. I got to make it a gift for her, I guess.

Taylor White: So, do you run all different types of machinery for this competition?

John Schiedeck: Yeah. So at the local one in San Antonio, I ran, I believe it was a 950-wheel loader. And then what was that? 301.5, I think. Little tiny excavator with expandable tracks, and then 320. So then, when I won that one, they sent me up to Dallas, and they have the same exact competition going on there. So the winner of that competition and myself went head to head in a little skid steer challenge where we had to grade the closest four inches below form boards in a tight little foreign board setup. So then North Carolina, they had a 315 that we had to do some digging with, 950. I think it was a 950. It reminded me of 966 and then a 420 backhoe. And I don't know what CONEXPO has in store. They won't release any of that. They said it's top secret.

Taylor White: It's top-secret knowledge.

John Schiedeck: Yeah.

Taylor White: That's pretty cool.

John Schiedeck: I heard at CONEXPO they're not even going to allow the other participants to watch the person that's doing the challenge at that moment. Because, like in North Carolina, everyone watches everyone, and you pick up tricks. One guy does something good, and everyone else does that. So I don't even think they're going to allow spectators or the competitors to walk.

Taylor White: Did you go first or last?

John Schiedeck: They kind of had it broke up. I never went first, but I never went last. I was kind of in the middle of most of them, yeah.

Taylor White: What a skill.

John Schiedeck: No one likes going first.

Taylor White: No, 100%,

[Advertisement] We are less than 100 days from the 2023 show. That's right. We are coming up on the largest construction family reunion in North America. ConExpo-Con/Agg is going to be here before we know it. If you have not registered yet, there's still time to secure your tickets. Visit conexpoconagg.com and use the promo code ‘Podcast20’ to get 20% off. That's right, 20% off with promo code ‘Podcast20’. If you already have your tickets to the show, join us in the countdown for the show and comment below to let us know you're going to be there and what you're most excited to see.

I was going to say, like, what a skill to be that good, to be able to go somewhere and do something that, regardless of what brand or machinery or whatnot, people don't realize just how hard it is to actually run a piece of machinery. Like anybody, what’s it - run or operating is hard. Like, anybody can run a piece of machinery, but not everybody can operate it, you know what I mean? It's pretty impressive that you can actually do that with the machine and be that good to where you're kind of recognized, you know.

John Schiedeck: Yeah, it is pretty challenging, too, even if you're experienced at it because you're not used to running brand-new equipment all day. And you jump on a brand new machine, and every machine has got its own little quirks, you know. And to jump on it and you don't know the quirks, they don't give you any warm-up time. You're just thrown in the fire; here you go, and it's pretty tricky. You got a real short window to learn that machine.

Taylor White: Yeah, there was an instance we plowed an airport here in Ottawa, and we have a Komatsu 655 grader, and it's an awesome grader. I love it– beautiful piece of machinery, awesome line of sight, everything. And I've never run a grader before. And the guy that normally runs a grader, he slept in one morning, and we had a patient transfer flying in, so somebody that needed to go to hospital. So I needed to hop in the grader super quick, and I had to teach myself real quick how to run a grader. And it's not a piece of easy piece of machinery to learn. I always say we call it praying mantis because, first of all, it looks like they always look like praying mantises. But you got all these– Is yours joystick?

John Schiedeck: Yeah, mine's–

Taylor White: Okay. So this has all these knobbies up top, and I'm like doing this, and one's moving the blade this way, one's moving it up this way, and then all of a sudden I'm pivoting the whole grader side to side, and then my tires are turning like this and that. With a grader, what was the learning curve like on a piece of machinery like that?

John Schiedeck: Well, I started on the H models, at the same the piano keys for praying mantis at the style like you said. My dad ran blade for, man, years. I can't even count how many years. So, every time he got an opportunity to let me on it, he threw me on it. And he'd do yell that by the boss, “Get him off there.” Then the boss would leave me, throw me back on, so I got a lot of just small windows of seat time. And then got fairly good on the H model blade and got thrown on an M at the company that I started my water truck and everything with. And that was the first time ever in an M. And the very first day; they stuck me in a little alleyway that was probably 12-foot wide with a 14-foot blade. And I broke a fire hydrant off with it backing up because the M, you can't see nothing behind you because of all the filter stat That's a big learning curve, especially trying to back up. But I gave it about four months, and, man, I started feeling real comfortable with it, and now I'll never go back. I mean, I like getting in an H because I feel like a real blade hand when I get in one. But the M is just so intuitive, and everything's right there goin' around, manholes. It's all one smooth move, and it just flows like water.

Taylor White: Yeah, well, I guess I don't know. I've always said this when we're hiring people or just getting a piece of machinery, having it in your blood. I always said it's in my blood. I remember being 10 or 11 years old, scooping out some dirt from a ditch, and I was running an excavator, and I remember my dad being like, you know, "How you like that? How do you like that, Tay?" And I was like, "Oh, I love it." And he’d be like, "All right. Well, tell me, you know, like how you're doing this, hand to that, and this?" And I remember saying to him, "I don't know, I couldn't explain to you how I'm doing it. I'm just doing it." And I remember him saying like, “ Because it's in your blood." And I remember him saying that, and I think that that's true too. Obviously, you can learn a skill, and I'm not saying that you can't, but I feel like when something is truly in your blood or operating, it's there, and I think that's what makes a really good operator stand out. Would you agree with that?

John Schiedeck: Yeah, 100%. Yeah. I don't know what makes it in your blood, but if you're raised around it, and previous family's done it, you're going to do it.

Taylor White: I agree.

John Schiedeck: Yeah. I mean, I got my son. He's nine years old right now. We're building some property up 16 acres just down the road from here, and I had him on my 299 yesterday.

Taylor White: I saw that. I wanted to say that it's super cool to see.

John Schiedeck: Yeah. He's better than half the people that I've seen run. He's only nine, so that makes me proud. A lot of the stuff that he was doing, he just picked up naturally—like, digging into a pile. He found out that if you just dig in the same spot of the pile, it gets harder and harder. So, he figured out to kind of chase the loose parts of the pile, and he was working his way around the whole pile. I never told him that. He just figured it out.

Taylor White: That's awesome. I'm always looking forward to those moments. I have an 18-month-old daughter and another one on the way, and I can't wait for those moments, excuse me, to share those with my kids. I think that's pretty special.

John Schiedeck: It is. I love every bit of it and wouldn't trade it for nothing.

Taylor White: So, your nine-year-old, does he have interest in, and obviously, he wants to keep it in the family then, operating?

John Schiedeck: I don't know yet. He's kind of in his own little things that he enjoys, but he loves running equipment.

Taylor White: He’s got some time.

John Schiedeck: Yeah, exactly. I'm not going to force him to do it. I'm going to let him kind of go where he wants to go and see what he picks up and likes to do. But one day, I'll get my daughter in the stuff, but right now, she'll just crash into anything. She's a nut. I catch her riding her motorcycle, standing on the seat, and she's only five. She's got a little PeeWee 50. That's pretty fun. She's a nut.

Taylor White: I think that's important to grow your kids up around that sort of stuff. And like you said, like little PeeWee 50. And I grew up doing that sort of stuff too. I think there's a lot of importance in letting kids do dangerous stuff safely. I always say that. I think that that's really important because you don't want them to be too coddled or be over safe or not let them do this or do that, because then they grow up in a world where everything's like, "Oh," and I feel like they find themselves that way too, maybe. I don't know. I think that that's really important. Learning like those motor skills and stuff like that from a really young age, those are skills that, even though she's just bumming around on a PeeWee 50, those are skills she'll bring with her for her entire life.

John Schiedeck: Yeah, core memories. And it's not just riding motorcycles; it goes into other things in her life like you said.

Taylor White: Yeah, 100%. I wanted to chat with you about technology. I saw a couple of posts that you were doing. You had some Trimble and stuff like that. What's your experience been like with GPS and technology on the job site?

John Schiedeck: Man, I love it. I wouldn't want to do without it. Everyone gives GPS a bad name in the industry, saying you're not a hand if you use GPS or something, but it's just a tool like anything else. And, man, you can't beat up a good operator with GPS. You could take a guy that's never run it before and stick him in, and he can run it for one that makes some production there. But a good operator that knows how to move the material and knows where he's at at all times, you can't even compare it.

Taylor White: So then here's something you said something there, so an operator that doesn't know how to operate 0:29:49.2 [inaudible] and they can still operate, you'll get production out of them. Is there value in that? Or is there value them not learning with GPS first and then going on to GPS? Or do you do that? You stick them on and say, "Hey, I'm getting my money's worth out of this guy. And so what? He doesn't know how to run it without GPS, but he's doing it?"

John Schiedeck: Yeah, I think there's advantages to both, but I really think throwing them in the GPS machine, they can learn how to manipulate the material with the help of the GPS. So I think it would help them pick up the learning curve faster in the machine. Because, like you said, with a dozer, you got to kind of know that tipping point; with the GPS, they will figure out that tipping point and see what the blade is doing and help them figure that out. Like right now, I'm kind of helping my brother out. He's learning to run the blade, and he knows how to run GPS fairly decent, but he doesn't know how to run the blade that well. He can move it and run it like you said, but not really operate it. And I'm able to give him pointers that most people would take a lot longer to pick up just doing it freehand, and he can figure it out with the GPS helping them.

Taylor White: So whenever maybe some listeners and I feel like I always skip over this, you might be a good person to get in-depth with this, but when we're talking about GPS, and it helps you operate and stuff like that, does it run the machine for you? Is it showing you grades, and you're still operating it? What is the GPS doing? What's the system doing with your machine when you're operating?

John Schiedeck: It's definitely not running it for you. It automates a lot of your functions as far as blade heights and that sort of thing. But you still, as an operator, have to know what that material is going to do because all it's doing is trying to go to grade. The grade you set it out, it's going to go to. I mean, you have to know if I got 3ft to cut right there; obviously, I can't take 3ft to cut in one shot. You got to know how to run the machine until you can get to a point where that GPS can take over and help you.

Taylor White: So you have your set of plans, and you have a separate screen inside your grader. And are you hitting pinpoints on it? Is it telling you, “Okay, this is the project for today.” Is there a task? Are you giving a task? How does it work?

John Schiedeck: No, you just basically have your set of plans, and the machine moves on those plans. You got a little machine icon, and it follows where the plans move on the screen. Your machine stays where you're in, obviously, but you kind of got to go explore the job and put your blade on the ground and see what the surface conditions are and kind of make a game plan of where you want to cut. Obviously, if you're going on a rough grade job, you're going to have your cut fill map that will kind of give you your heavy cuts and your heavy fills. But when you start getting down to the nitty-gritty, you got to have that blade on the ground and know, “Hey, there's still quite a bit of cut over here,” and then know where your fills are at, and just driving around is the only way to figure that out.

Taylor White: Because obviously, you do fine grading; I mean, like, how close is the GPS getting you? Like within cents?

John Schiedeck: Yeah. So this job I was just doing up the road for those big apartment pads, I was within two hundreds on it, and it's a nice wide open field: no trees, no obstructions, just a good clear satellite signal. And on a good day like that, you'll get it within the hundreds.

Taylor White: So the weather does– If it's a cloudy or rainy day, you might do a worse job because the signal is not as good.

John Schiedeck: No, the clouds don't seem to affect it that much. What affects it the most, like, buildings and trees, because it's triangulating out of the sky. So anything that blocks, if there's a building there, obviously you're not going to get your signal down where it's trying to triangulate. So you'll lose satellites, but yeah, without any obstructions, easily 500 is all day long.

Taylor White: That is crazy. How long has that been on your machine? Like, how long have you been using technology? And is that something that when you're an owner operator that you were like, "Okay, I'm going to buy some machinery, and I'm going to operate it and rent myself out? I better buy some technology along with this." When did that investment– Because it's a big investment, it's expensive, this technology. So when did you think, "Okay, this might be something I should invest in?"

John Schiedeck: It was day one when I bought the machine. I had to have it in California; if you don't have it and you're trying to do any kind of owner-operator work, you won't stay busy without it because all of the big contractors use it. And they're not going to put a grade setter with you all day long to babysit you. I mean, a lot of the jobs there, they didn't even have staking. You check in on one survey point at the beginning of the day, and everything checks out, and you go. Yeah, it was an investment from day one. Had to have it.

Taylor White: Is that something that– How steep was the learning curve whenever you started using– How many years ago was that?

John Schiedeck: So I started learning it when I was working for the company that did the water truck stuff with, and that was in 2013 and took me about a year. I mean, you could pick it up, the general basics of it, within a few weeks and get pretty productive at it. But to really get the ins and outs and all the deep features that people don't use that often, that took about a year. And even now, I'm still finding stuff that I never even knew they could do. So I'm still learning with it.

Taylor White: That's really neat. Is it something that you would recommend to somebody that was– Being an owner-operator, obviously, you said it's super hard to stay busy without it. Would you be like, "Okay, you're going to get a machine, and then you're going to want this." And have you always been Trimble, or has it been somebody else, or why Trimble?

John Schiedeck: I've run Topcon on other people's machines and stuff, and it's a great system, but I've just never really cared for too much. But most of the contractors that I knew that I was going to be trying to go to work for with my blade ran Trimble. And so that's the reason I went with Trimble because that's what everyone had. And you can still run Trimble with Topcon based, but you have to have a special radio that reads with Topcon frequencies and stuff, which you can get around that. But yeah, like in Texas, if I started here, I would probably have gone with Topcon because a lot of the contractors here run Topcon. But that's just how it worked out for me, running Trimble.

Taylor White: How have you seen it change over the years the technology of the GPS? Like as far as, like, this is our newest and greatest screen, this is our newest and greatest software release. Has it changed immensely? Has it changed not much?

John Schiedeck: It's changed tremendously in 17 years that I've done it. I remember when they were first testing out, I believe it was Trimble. It may have been Topcom, but it was a backpack unit that the Grade Center had to carry as a backpack and walk around on the job. And when I started my first company, I worked for it; it was all pulling tape and hubs and doing staking and all that. And you'd have a 10-foot cut with a stake in the middle of the pile at the top of it, you know, so you didn't wipe it out. But I remember that the very first day, we got our first Trimble rover. But everything before that was all like Topcon system five, where you got your laser receiver with the monkey that ran up the pole. So it's changed tremendously, especially like my machine running mastless now on the blade. That's a huge game-changer for motor graders.

Taylor White: What's that? A no-pole?

John Schiedeck: No GPS poles on the corners of the blades anymore.

Taylor White: So that's something new they just came out with?

John Schiedeck: Yeah. So I believe– Topcon has it. I know for sure in the John Deere machines. I think they have incorporated it in the other manufacturers as well, but Trimble has it for Cat. And before you had the poles on the end of the blade and you had to be really careful that you didn't hit your cab with a GPS receiver or you didn't hit your front light or whatever on your other receiver. And you're always watching those heads rather than kind of watching your work. And then, it limited the mobility of the motor grader. There's a lot of things that, you know, like trying to cut a back slope or something, and you'd swing your blade out to the side. You'd have to be really careful with that or not even do it at all because the mast would be in your way. And to eliminate those has brought back all the versatility that a motor grader had. I can spin my mobile around 180 degrees where it's facing backward now and grade backward with it if I want, and I've done that quite a bit. I was working on a freeway job on Interstate 5 in California right after they put the maskless on, and we're doing median work, and there was no way to turn around unless you drive 5 miles down the way. There'd be times when I just spin my blade around and blade backward and make some grains or fills and then turn it back around and cut it to grain.

Taylor White: That's crazy. Where do you see it going from here? What's something that you are like, “Ah, they should really do this with it next”? Where does it go from here?

John Schiedeck: Oh, man. On a motor grader, I really don't know. It's almost perfect.

Taylor White: Yeah, that's what I mean. That’s why I asked. It’s almost like, Where? Where can they go with it?

John Schiedeck: Yeah, I mean, I've seen and heard some rumors in the industry of them using, like, LiDAR on the front of the machines that scan so you can see what material you have in front of you. That would be a pretty cool feature to incorporate into it, so it's always a running tally of how much cut or fill you have. You don't have to– Like I was explaining earlier, drive around the job and figure it out. It kind of records it as it goes. That'd be pretty cool.

Taylor White: Wow. Yeah. I mean, I feel like with the technology and stuff, there's just such a– I feel like there's always something new coming out, but I feel like in construction, at least, it took a bit for the technology. And to be honest with you, like, GPS up here, it's obviously huge; it's massive. But, like, guys in our line of work, a lot of the residential stuff, they're not really using it. I'm a big advocate for it, even though we don't have it. I've never even used it. I've used it on some job sites just because some other companies were there. Walk around with the guy with the pole stick and kind of, like, mark out stuff and just that aspect of it. But as far as being on a GPS-guided machine, I've never done that. And everything that I've been told is– The smaller residential guys I mentioned are like, “Why would you use it on a septic or a house dig? That would make no sense. You don't need it.” What do you say to that because I'm generally curious. Because I want to make the investment in technology, but people are like, “No, just for house digs and house digs and laneways and septic, you don't need that.”

John Schiedeck: Well, man, maybe for septics, it might not be the best thing for that. I still think it would be because you could do an infield design and carry percentages for flow and all that; you need that. And to have that right at your fingertips, and you don't have to grade check and shoot it with a laser, that would be a huge benefit. But for house digs, man– Perfect example I could think of would be Ryan from Rock Structures. I know he uses it on all of his house digs. And you have no stakes that you have to worry about knocking out everything's right in front of you on your plans. And when you hit grade, it does grade for you. I mean, if you're doing any kind of work doing house digs, that's a huge game changer.

Taylor White: I think my old man, when he's listening to this right now, I think he should value that because seriously, he is the biggest advocate for saying, like, “No, we're not spending $100,000 or whatever to outfit stuff.” But I could count so many times this year where we've gotten a caller from the builder, the homeowner being like, “Your boys ripped out the stakes. I got to get the surveyor back. It's $400 now. We're going to charge you those $400 because the boys and they didn't do it on purpose, but they just backed over a stake, a corner stake, and now the forming guys have nothing to measure it.” And we don't know, is that the four-foot offset? Did you do it correct? You know.

John Schiedeck: Yeah.

Taylor White: So, I mean, just right there, even when you say that it makes so much sense to do that.

John Schiedeck: Yeah, you're doing the house stake; you wouldn't even have to worry about where you're throwing your spoils. A lot of times, they get in your way, and you could just throw it right next to you and not worry about wiping out your line work or stakes. And then, when you move over to the next mast, move it out of your way, and you still got all your grades right there.

Taylor White: No, I think that's really important.

John Schiedeck: Huge benefit. Yeah.

Taylor White: And then I think that's across the board with technology. Is there anything else in construction, like technology, that you kind of like that you utilize and use a lot? Like as far as not just grades, but just other stuff, like whether it be in the machine or–

John Schiedeck: Not so much, really.

Taylor White: Just GPS.

John Schiedeck: Yeah. And a lot of it's coming incorporated into the machines now. Like, all the new Cat excavators have the 2D grade control incorporated, which is really an awesome feature. I hope Cat rented me one to kind of practice with the operator's challenge and stuff, and it had it, and I dug my whole house pad with it. Never pulled the laser out, and I went and checked it, and it was within a tent with just benching your teeth and backing up and benching again. That's pretty cool.

Taylor White: Yeah, it is.

John Schiedeck: Stuff that's coming out.

Taylor White: Yeah. And I think what's really cool is there's going to be like– What's cool about the CONEXPO show is that you get to see a lot of that stuff. And obviously, people showcase the best of the best, whether it be Cat or your Komatsu or John Deere or Dusen or Sandy or Hyundai, or all these brands that showcase the best of the best or Topcon or Trimble or Leica. They show off kind of what they have up and coming. And I think that that's what's going to be really cool. And that's what's cool about the show is seeing what's coming up and what's next. What, as far as the show, do you look forward to at CONEXPO? It doesn’t have to be– Maybe it’s having beers with the guys and just networking, but what are you looking forward to at the CONEXPO show coming up in March?

John Schiedeck: I like the technology side. I like seeing, like, the Trimble side. I mean, Topcon and Leica, like you said, but Trimble for sure because I run it, and seeing all the new things they're coming out with that you don't ever get to see, I mean, that's amazing. And obviously all the new equipment. I really want to get myself an excavator with a tilt rotator, so I like seeing that kind of stuff. And I know there's a lot of different brands at CONEXPO that are showcasing their stuff there. Everything at CONEXPO is just amazing. If you have any kind of interest in this industry, it's really awesome to check out.

Taylor White: Well, I look forward to seeing you there, and I thank you for coming on the podcast today and chatting with us about this. And hopefully, everyone can catch up with John at CONEXPO in March.

John Schiedeck: Yeah, I'm looking forward to it. I can't wait. I know I got a lot of people I got to meet up with.

Taylor White: I know. List never ends.

John Schiedeck: Yeah. I hope I can at least see the show a little bit.

Taylor White: Well, there's a lot of it to see.

John Schiedeck: Yeah.

Taylor White: Awesome. All right, John. Well, thank you for listening to the podcast brought to you– Thank you for listening to the CONEXPO-CON/AGG podcast brought to you by our good friends over at Komatsu. John and I shall see you in March. Take care. Thanks, John.

John Schiedeck: Thank you very much, Taylor.

Taylor White: [Advertisement] We are less than 100 days from the 2023 show. That's right. We are coming up on the largest construction family reunion in North America. ConExpo-Con/Agg is going to be here before we know it. If you have not registered yet, there's still time to secure your tickets. Visit conexpoconagg.com and use the promo code ‘Podcast20’ to get 20% off. That's right, 20% off with promo code ‘Podcast20’. If you already have your tickets to the show, join us in the countdown for the show and comment below to let us know you're going to be there and what you're most excited to see.