If you’re paving highways today, you’ve already felt the shift: sensors on the screed, compaction systems that “think,” and cloud tools that keep the plant, trucks, paver and rollers in sync. Semi-autonomous paving is the steady layering of assistive automation that improves quality, safety and production without removing the operator from the loop.

WHAT “SEMI-AUTONOMOUS” LOOKS LIKE IN PAVING

On the paver, 2D/3D machine control keeps grade and slope locked in, while material-flow automation helps maintain a consistent head of material—all to reduce segregation and yield variability. Platform examples include Trimble Roadworks (now extending across the milling–paving chain) and Topcon MC-Max Asphalt Paving, which scale from entry-level 2D to fully automated 3D.

On rollers, intelligent compaction (IC) systems measure pass count, stiffness/EV, temperature and location—guiding the operator to uniform density with fewer passes.

WHY IT MATTERS: QUALITY, SAFETY, PRODUCTIVITY

FHWA tech briefs reaffirm that IC and related intelligent construction technologies reduce variability, cut rework and improve uniformity—big drivers of lifecycle performance and warranty risk. They also help crews make faster, safer decisions by surfacing actionable data (temperature windows, soft spots and under- or over-compacted areas) in real time. In short: tighter mats, fewer callbacks and better documentation when an owner asks for proof.

PAVER + ROLLER ECOSYSTEMS ARE GETTING SMARTER

VÖGELE’s WITOS Paving suite shows where semi-autonomy is headed on the mat: WITOS Paving Docu/Plus now integrates RoadScan thermal imaging and a Jobsite Temp smartphone app so supervisors and roller operators can see pave speed, screed width, truck positions and live temperature maps—then coordinate rolling patterns without radio chaos. Pair that with Topcon MC-Max or Trimble Roadworks and you’ve got a connected, semi-autonomous workflow from mill to final roll.

On the roller side, OEMs are embedding more automation to “set it and forget it” (with guardrails). Dynapac’s SEISMIC Asphalt technology automatically tunes vibration frequency to the mat’s characteristics—up to five adjustments per second—cutting fuel use and improving density while reducing operator fatigue.

BOMAG is pushing open, mixed-fleet data. Its BOMAP Pave app links pavers and rollers (any brand) to share temperatures, compaction and stops in real time—supporting coordinated rolling and one-click reports for owners. That openness matters as contractors mix legacy machines with new gear across projects.

OWNERS ARE FUNDING THE DIGITAL SHIFT

If you need a nudge to invest, look at the money: FHWA’s Advanced Digital Construction Management Systems (ADCMS) program is seeding DOT projects that use 3D models, connected workflows and digital QA/QC—exactly the ecosystem semi-autonomous paving runs in. Recent rounds funded eight states and opened multi-year NOFOs through 2026, signaling strong owner appetite for digital delivery and data-rich paving. That creates spec language—and pay items—that reward your tech.

WHERE TO START (AND WHAT TO WATCH)

- Begin with outcomes, not gadgets. If smoothness incentives, density bonuses or night-work windows drive your profit, target features that affect those items—e.g., 3D control on the screed, thermal mapping and IC with pass mapping. Use the tech to prove compliance and protect margins.

- Connect the chain. The biggest gains show up when the plant, trucking, paver and rollers share context: real-time truck ETA/tonnage, pave speed, temperature bands, and roller target zones. Semi-autonomous tools allow you to do this without ripping out your entire fleet.

- Standardize workflows and train. Semi-autonomous features shine when operators trust them. Build quick-hit SOPs (start-up checks, sensor health, target windows, acceptance criteria), run short crew drills, and appoint a “paving technologist” to own calibrations and data handoff to the owner. FHWA’s IC/ICT resources include practical checklists worth borrowing.

- Mind specs and data deliverables. Ask early about model formats, temperature/IC data requirements, and how the owner wants documentation. ADCMS-funded jobs in particular will expect digital submittals—plan your exports and cloud permissions before you mobilize.

- Watch the market moves. Vendor ecosystems matter for support and upgrades. One example: Volvo CE’s ABG paver business moved to Ammann in 2024—useful context if you run or service ABG machines and are planning future purchases.

BOTTOM LINE

Semi-autonomous paving isn’t about replacing crews—it’s about giving them measured, repeatable control over variables that used to be guesswork. Start with the use cases that hit your incentives, connect the plant–paver–roller data loop, and let assistive automation do the boring parts flawlessly. Your operators stay in charge; your mats, density and documentation get better—and owners are increasingly willing to pay for that proof.

Take the next step and see if retrofitting your construction equipment for autonomy is right for you and then check out this podcast where EJ Herron talks about bringing GPS and 3D systems to your jobsite

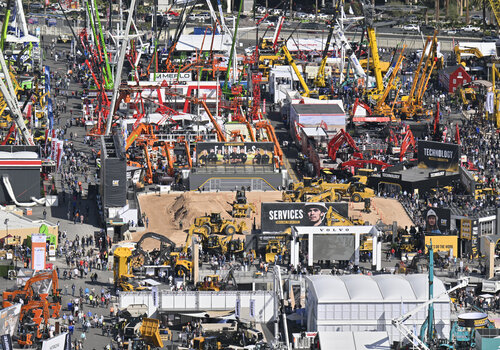

The latest in paving technology will be on display at CONEXPO-CON/AGG 2026 March 3-7, 2026, in Las Vegas, Nevada. For more information on CONEXPO-CON/AGG, visit www.conexpoconagg.com.

Photo credit: SHUTTERSTOCK/STOCKR