The visionary behind Dig-It Digital GPS, Eric "EJ" Herron, joins Taylor White on the podcast this week for a fascinating journey through the cutting-edge realm of construction technology. Together, they explore its profound impact on the industry's efficiency and precision, and the exciting possibilities that lie ahead. Whether you're a construction professional seeking to stay at the forefront of industry advancements or simply intrigued by the latest in technological innovation, this episode promises an engaging and informative experience.

As shared here today, EJ's personal odyssey, from his early encounters with Caterpillar to his role as a trailblazer for technology adoption at SITECH South, provides a riveting narrative of the construction industry's evolution, exemplifying the transition from conventional practices to the transformative power of GPS and 3D modeling. His discussion with Taylor also delves into the pivotal role of GPS technology on construction sites, demystifying the intricacies of base stations, satellite corrections, 3D models, and machine sensors. As you will hear, the real triumph lies in the profound impact on precision, efficiency, and a dramatic reduction in rework. Today’s episode lays bare the imperative for construction companies to embrace technology as a formidable competitive advantage, quelling the apprehensions surrounding its adoption and highlighting the benefits that extend far beyond improved project outcomes. With glimpses into the future, including the potential for autonomous machinery, EJ and Taylor leave no doubt that the construction industry is at the precipice of an exciting technological era, one that EJ will be documenting and showcasing to the world at each momentous step along the way.

Topics:

- EJ's transition from traditional excavation to embracing modern construction technology

- The pivotal role of GPS technology in construction

- The competitive advantage gained by construction companies through technology adoption

- Strategies for integrating GPS technology into construction projects and winning bids

- The future of technology in construction

- Attracting a new generation of talent through technology's appeal to younger individuals

- Leveraging social media's reach and influence to connect with employees and clients in the construction industry

- The impact of technology on improving project precision and efficiency

- Some real-world examples of technology’s success in construction projects

Watch now:

Listen now:

Listen on your favorite app: Apple Podcasts | Spotify | YouTube

Subscribe to the CONEXPO-CON/AGG YouTube channel to be notified of new episodes.

Join more than 54,700 industry peers who receive construction industry news and trends each week. Subscribe to CONEXPO-CON/AGG 365.

Episode transcript:

Taylor White: Welcome back, everybody, to the CONEXPO-CON/AGG Podcast. I am your host, Taylor White. As always, this podcast is brought to you by our good friends over at Komatsu with those beautiful, beautiful yellow machines. Today, with me, I have somebody who I'm definitely looking forward to speaking about the technology side of construction. Don't normally get to dive into that so much. EJ with us here today from Dig-It Digital GPS.

EJ, thanks for being on here.

EJ Herron: Hey, Taylor. Appreciate you inviting me. It's awesome to be part of the show.

Taylor White: Yeah. Listen, and I was saying before this, I appreciate it. I know we've rescheduled a couple of times, so I really appreciate you coming on here today and adjusting that and it means a lot.

EJ Herron: Oh, absolutely. It's like a typical construction schedule. Go with the flow and make it work.

Taylor White: Yeah, 100%. So why don't you start with telling us a little bit about yourself. What are you into right now? What's your claim to fame?

EJ Herron: Well, I suppose posting awesome construction videos, heavy equipment. I try and focus on the technology side of things primarily because I work at SITECH South in Atlanta, Georgia and promoting now as far as the Trimble equipment goes, the GPS, site surveying equipment, it's all something new for a lot of people still. A lot of people are still picking up on it, how does it work, and what's it going to do for me. So I like to showcase that on my videos and on social media under Dig-It Digital GPS.

Taylor White: Yeah, you have a ton of stuff just showing machines, whether it's a dozer, pushing some dirt or an excavator or the guys in the trench. What are you seeing? Kind of like what brought you into that industry, what brought you into this side? I know that maybe you've done some excavation beforehand, but what got you to where you are now?

EJ Herron: Well, I've always been curious with construction equipment since I was a kid and I grew up in Peoria, Illinois around Caterpillar. A lot of family members working at Caterpillar and then I ended up working there as well in the engineering side of things. But just being around equipment and wanting to do more, wanting to learn how to run it. I started an excavation business and learned how to run these machines myself. Learned all kinds of different construction trades as far as like, utilities and digging foundations for new homes, apartments. Just tried to get into every aspect of using a piece of heavy equipment. Then from there, it just kind of branched out to the technology side at Caterpillar after I had left my business, learned the technology that Cat was providing, kind of with Trimble.

And then the opportunity popped up at SITECH South in Atlanta that they needed a sales manager down there to help promote the technology in the industry and in that region to go out and help customers put this on their machines, get their crew set up so they could go out and be more productive each and every day.

Taylor White: Yeah, and obviously, being in excavation, you would have saw that there's this massive need if you were doing excavation in apartment digs or home digs or whatnot. I mean, whenever you're doing final grading, you got the guy with the laser stick doing all the stuff and then now you have machine control. We've come so far from that. So was there a passion? Did you see the need for that in the industry? And that's where you're like, you know what, I like doing the excavation, but this is kind of what I want to dive down into more because the industry kind of needs it.

EJ Herron: Yeah, it was like the next step for me because I had first hand knowledge of some of the design with these machines.

Taylor White: Wow.

EJ Herron: I ran the machines and I used them every day. And yeah, like you said, with the grade checker out there, I could put him out doing something else, doing a better job or doing a different task for the day instead of just following me behind the bucket, making sure that I was on grade with the excavator. It would be a dig, make a pass, and then he would double check it again. And then I'd make another pass and then he'd check it again. Well, shoot, if I had that 3D system in my excavator back then, I could have probably dug the basement at least 50% faster, 60% faster maybe. And I could have had him moving dirt over to the side somewhere where it was out of the way instead of me having to do it with the excavator.

So we use lasers. That was kind of the thing then. But seeing the lasers still out there being used, people aren't using the 2D systems even. So I talk about that as well.

Taylor White: Yeah, it's totally true. We still use lasers as well, too. And yeah, I find a lot of the time the guys aren't even using all the technology that is handed to them in the machine because of that. And when you go into GPS, you kind of unlock this next level. It's like a video game. It's like level two has now been unlocked because you have this range that you can actually cover on the job site or the technology, that machine that you're actually paying for when you buy the machine.

But what I want to know is, I want you to explain, I guess, because you'd be a great person for this. How does GPS, the technology, how does it actually work? Okay, you have a base station and this and that. Can you explain that to people listening right now? How does GPS work to where you put in a grade on the machine and it's doing it well?

EJ Herron: Yeah, basically you do have a base station, and that's either a local base station or you can subscribe to a service where you get the corrections over the air. But I'd say probably 90% of contractors are using the local base station. So you set that up and what that does is it’s giving corrections to any machine that’s on the job site. Basically, it pulls in a tighter accuracy to your location.

Taylor White: Through what? Satellite?

EJ Herron: Through satellites, yes. And then you have a 3D model that somebody has either designed for you or you've done it yourself at your office using software. And you take the engineer's plans, create this 3D surface that your machines are going to go out and build on the site, load that into the machine. And with the machine system, you have GPS receivers that are typically either on the cab out on the blade, you've seen mast out on the blade before. And then you have sensors that tell the blade the different pitches that it's doing, as well as the machine will have pitch sensors as well. And then the operator sees a screen inside the cab with the model on it and his position on the job site. And it'll tell you, based off of the blade tip, bucket tip, or whatever you're using, where your blade is based off of the model on the job site. And so that helps guide the operator to know where he's supposed to dig, grade, push dirt to see where his cuts and fills are.

Once you start using it, it's pretty intuitive. New operators really pick it up quick. It helps them become a better operator quicker. But the experienced operators, when they start using the 3D GPS, it really makes them like experts. They can really go out there and do some work.

Taylor White: Yeah, I think it's so crazy, everything that you just said, it's so wild when you think about it. Where we’ve come from since the 1940s, 1950s construction equipment to now. It really isn’t in the span of time really isn’t that long. And now we have these things where you have this base station that's talking to the machine. And the machine has technology built into it that knows where the bucket is, which knows where it's placement is on the job site, which knows the job site plans and grades. It's really a wild thing. But why would you say, if someone was like, why do I need GPS? What is the importance of the accuracy on the job site for production or final product?

EJ Herron: Well, with the GPS systems, I think you end up doing the grades or the work faster and you also are doing it once instead of guessing if you think you have it to grade. A lot of operators say they're really good, they can see a grade by eye. I hear that every day. But then you get the GPS system out there and well, it's off. So what happened? Did you not measure correctly with the staking or did you have your dozer at a wrong slope and you thought your eye was good? But at the end of the day with the GPS system, you're going to be more accurate being able to do it the first time instead of coming back and fixing anything.

And a lot of people are just scared with the technology, trying to figure out who's going to run it, who's going to be in charge of it. If we buy this, is it going to be put to good use? Are my guys going to actually apply it or is it going to sit in a closet somewhere and collect dust? It's not something that you can easily just purchase off the shelf and if you use it, you don't or it's very expensive. But so is another machine. Instead of buying several machines, maybe you buy one machine with GPS or technology on it and that can do just as much as maybe two or three machines can.

Taylor White: Yeah, 100%. You mentioned that new operators, it's great for new operators because it helps them. Do you truly think that it is good for new operators to learn on a machine with GPS? Or do you think it's better to learn without GPS? Because that's a big debate, right? I have an experienced operator. When we tried a Trimble system this year and we put it on a Komatsu Dozer actually, and it was the I version, the D, I forget was a 55 or something like that. And this kid could run a Dozer, no GPS. Put him on the one with the GPS and he nailed it. It was amazing. But do you think it hinders good operators because they're not learning how to do that manual keeping grade versus with GPS or what I'm saying just doesn't make sense.

EJ Herron: What you're saying makes complete sense. So there's different trains of thought with that because everybody learns differently. Some learn through application, some learn by watching videos, others learn by watching others do it. I myself, I learned how to operate equipment without any technology. So I'm kind of old school that way. I would say if you had some small task that you could set somebody out, like on a Dozer and just start grading a pad, let them play with the controls and focus on the machine, understand the limits of the machine, how it functions, the controls, and then once they get good at that, give them a machine with 3D on it, just like you said with your operator. Then they understand the functionality of it. But then once they get the 3D, it just opens the window and it says, okay, this is what I'm now trying to get done for the day. This is my productivity area here that I'm focusing on.

For an excavator, you do need to learn how to run the controls to dig a flat trench. I would say put somebody on a machine to start loading trucks first or do cleanup, and then let them start gradually moving up to grading footings, using technology to help them with that. And then you don't put somebody out on a mainline pipe trench, putting in storm sewer, sanitary sewer, when they're new. You got to have some experience. Just so I think with the 3D, you still need to have some experience to get going.

Taylor White: Yeah. You mentioned being scared, and as a business owner, I can totally speak to that because of the worry of, like, we did a rental on one for a commercial project and then it's afterwards, it's like, okay, well, price is set to actually buy it, and it's a big investment. It's not 20,30, 40. I mean, I'm talking Canadian dollars. It's 60, 70. That's not machine control even included in that. So it is a massive investment. And I guess I was scared of, okay, are we even going to really use it on maybe some of our smaller projects and not the big commercial projects if the big commercial projects don't keep coming? What would you say to other people that might have that kind of fear from the business owner standpoint?

EJ Herron: Yeah, it's an investment. But what I tell people is if they're not going to get into technology, I think they're soon going to have to get into another business, another line of work, because people with the technology are just going to get the work done a lot cheaper and a lot faster. So there's ways that you could acquire the technology. So, like, at my SITECH, we have rental options, we've got RPO options. You can finance the equipment. It is an expensive jump into it, especially like if you need a base station and a Rover to get started, plus a machine system, you're talking over $100,000 to get started. But there's been some conversations I've had with contractors, and I look at their fleet of pickup trucks, and they bought two or three new pickup trucks recently. And it's like, those aren't cheap, but do they make you money? It's like, no. Well, they get your guys back and forth to the job. You could probably get by with a cheaper pickup truck and buy the technology because over time, that technology is going to give you a better ROI. So you have to balance things out and get it to work with your books. Try and understand that investing in the long run is going to help you.

Taylor White: Yeah, I totally agree. The point that you made about the pickup truck made me think it's true because we'll sit there and think, maybe I can't afford that or do that right now. But yet a good deal on a three quarter ton comes by and we're like, wow, we can use another three quarter ton diesel.

EJ Herron: I'll just snatch it up.

Taylor White: Yeah, that is very true. You mentioned that in construction, you can't really get it further without adopting this technology. And I would say I agree. I think that you could still have your construction company, but I think at some point you might kind of get left behind or miss out on some projects that the scope requires, GPS or larger scale projects. So really growth would be hindered by not adopting the technology. Do you think a part of what you're doing is a key role of selling this machinery and helping people adopt that technology?

EJ Herron: Yeah, in my role, I'm not only doing sales, but I'm kind of consulting. So I help these contractors think about planning their jobs, how they're going to attack it, and how technology can help that. So let's say somebody's bidding on a project and they're not using technology, they go off of all the engineering inputs, cut fills, how much material you're going to move, and you actually go out to the site. And it's different once you get started. So a lot of times you'll throw in a change order for that difference. But if you can go in and quote it correctly the first time before you get started, I think you have a better chance of winning. And that's through a good 3D surface model, it's through maybe flying it with a drone first once you get the area cleared so you have a good cut fill map and then incorporating that with your 3D systems. So there's lots to think about and consider when you're quoting against other people and they're trying to do the same thing and get their quotes as tight as possible. So if every advantage you can take to put more money into your pocket, the better.

Taylor White: Yeah, you're dead right on that. Especially right now. What we're seeing is the past three years in construction have obviously been wild times. I mean, you throw a number at somebody or a project and I mean, not just willy nilly any number, but it was less competitive because there was so much demand. And now that people are really watching where they're spending their money, or big developers are maybe not doing as many big projects, we're really seeing the jobs that we're quoting. The profit is just getting smaller and smaller in terms of where we're actually able to price the job. So kind of what you're saying is use the technology to really help you if you end up getting the job, be efficient on the job site because you'll be able to track what you're doing as well too. And you're not over digging, so you're not putting in more aggregate than what you priced for. That sort of stuff is super helpful.

EJ Herron: Yeah, you're not burning more fuel every day with these machines too. So if you can dig it to grade the first time or get it graded with your dozer closer than what you were before and not have to make so many passes, that's less fuel that you're burning each day.

Taylor White: Where does technology keep going then? Like I said, it's insane to see where it is now. There's obviously videos online. You see people with autonomous dozers running in big mines, open mines, and then rock trucks that are just going point A to point B. Where do we go from here? And then what would the timeline be? Because I feel like so many people, even our size company, medium sized company, haven't really fully adopted GPS and the technology yet. So is it first everybody has to get on board with that? Because I remember my dad speaks about whenever excavators first started coming out because he used to use just track loaders to dig basements, right? Like rather than digging a hole, they would ramp down, dig and everything was like old machineries, right? And I remember everyone was like, those are terrible, don't buy an excavator. And then everyone adopted the excavator and now everyone's getting roto tilts. So people are getting ahead with technology. But where does it go from here? Or do we first need to fully adopt what's happening now?

EJ Herron: Yeah, it seems like it's lagging for the construction industry compared to everybody else, especially like manufacturing. They're using all this automation and robots and everything, but as far as construction goes, we're all old school still. We just do it like grandpa did. Yeah, I can see that autonomy is going to come out, but it's probably still out there in the future. We're still trying to get people just on board to use 3D just to begin with. So we do have 3D systems that are autonomous as far as being able to steer and follow horizontal lines. So new dozers are coming out with that horizontal guidance system where the operator can pick a line and just kind of follow it, let the machine follow it. He's directing the blade to get rid of the material and it's staying on grade with the 3D system that you're using.

But as far as construction being compared to mining, if you look at mining operations, they're pretty consistent. Day after day construction, it changes every day. Somebody can throw a wrench into things and the autonomous system would just not work. So we're trying to make that work as far as the 3D system, like a basic system.And I know that they have these rollers and packers that will follow a dozer that can be run autonomously. And it's pretty simple. It's pretty easy to do that. But to have a dozer go out and start just finishing grading a site that's more complex, and you got a lot of people on site versus a mine. So I know that they're looking at several different systems that would detect people, objects. We have to have all that in place first before you can actually have a fully autonomous site. I would guess maybe 10 years from now, you might start seeing these.

Taylor White: Yeah, I tell my guys all the time, don't worry, your jobs won't be taken anytime soon. Because when you're on a residential site or construction versus mining, you have foundations, you got septic tanks, you got trees, you got soft spots in a mine. It's kind of like you said, A to B every day.

EJ Herron: Yeah, it is pretty straightforward.

Taylor White: Yeah, exactly. What would help then, these construction companies such as myself to get on board? Is it more technology education? Is it through conversations like this and getting the word out about it? How do we spread that? Like, hey, everybody should try to be utilizing some GPS.

EJ Herron: Well, if you think about it, it's not just the technology, but it's the thought of what are my pain points? And I ask this to customers or contractors that are in this industry a lot, like, what keeps you up at night? How do you solve that? Is it a labor issue? Are you having a problem attracting new operators? Yet technology can help with that because these young guys like to play video games. They grew up with video games. They're on their phones all the time. If you run technology that's something that's similar to that and they can relate to it, they can pick it up pretty easy. You can also attract new operators over to your company because you are using technology. And they feel like, well, if they're a company that's using technology, maybe they're more advanced, maybe they're gaining better jobs that I can work on, newer equipment that I could operate.

And then also going back to what keeps them up at night, is it cash flow? Is it, I'm burning too much fuel? Like we talked about previously, the technology can help with that. Maybe you're not able to track all of the dirt that you're moving, so you're not getting paid for what you're actually performing on the job site. So with technology, that's another area that can help you.

Taylor White: Yeah. And when you talk about exactly like what you did, you have a heavy presence on social media. And I do the same as well, too. I've connected with all my employees that we have now that we've hired within the past three years have came from social media. So I kind of share that same retrospect of putting what we want to do out online and getting the word out that way. And that's what you've kind of done as well, too. And what got you on to doing that? What made you think, like, “Hey, I should probably start promoting what I'm doing on social media”?

EJ Herron: Well, I've just always had a love for this industry. And we would do demos with 3D systems on machines, and I would take some videos here and there, and different contractors would ask me, what does a 3D system do? How does it work? What's it going to do to help me? So I would take these videos and text them to them, email them to them. I was like, well, this is a lot of time to do this. Also, why not just share this on social media so that everybody can see it?

Taylor White: That's awesome.

EJ Herron: I think it's beneficial that everybody sees this, and it would help with my exposure, getting the word out there, showing that technology is a great thing to have. And so I created the Dig-It Digital GPS account, started sharing these demos, the different types of machines that we were setting up at SITECH South, and then just showing what contractors are doing every day, sharing that lifestyle. And then it gradually just got me more interested in getting the message out for reaching other people who weren't in this industry to decide, maybe I want to make this a career path, and maybe I want to get into heavy equipment. Because you keep hearing all these contractors every day say they can't find people. How do we gain these people and how do we get them to become operators?

And social media is such a great tool. The young generation is on it. I'm on it, but I've already got a career. But I want to showcase what I'm doing so that others are interested in it and they can see what I do day to day and what's out there.

Taylor White: Yeah. Well, I mean, 115,000 people obviously find what you're doing is interesting because that's how many people follow you on Instagram.

EJ Herron: Yeah, I know. It just blows my mind. It's crazy to think that there's–

Taylor White: That’s a lot of people. Yeah. You have family? You got some wife and kids?

EJ Herron: Yep, yep, wife and three kids. Two are out of high school, one's in the Air Force, and one is going to two-year college.

Taylor White: What did they think about dad being a social media star?

EJ Herron: They don't say much about it. It's funny because I send videos on there and they're like, “Yeah, I don't really care about tractors too much.” “Don't you remember riding with me in the machines and going out to job sites?” “Yeah. Okay. Well–” I think secretly it's like they like to see that stuff. They follow me. And when they were trying to decide on a career, I was pushing for, like, do what you like to do. Don't think that you have to do what somebody else says you need to do. Like, you don't have to go to college if you don't want to. You can consider a trade. You can consider going to work.

And then my oldest went to the Air Force because that was a good path to go out and just learn something and start getting some knowledge with some experience behind your belt. And then my second son, he decided that he wanted to go to a two-year college first. He's working part-time, going to school. He'll probably go to university. He's really smart, a lot smarter than me, probably, but he's doing some good jobs out there. Part-time work at Lowe's and one at the Ford dealership. So he's getting some experience.

I just said, pick something that you like that you have interest in, and that's what I've done. I've always had an interest with heavy equipment, so I'm doing something I enjoy. It doesn't become something that's really difficult for me in this job. And it's not hard because I enjoy it and I enjoy working with the people and helping them and seeing them succeed.

Taylor White: Yeah. Well, the passion definitely shows. I remember when SITECH came out to Earth and they had drones and they offered a stockpile takeoff. They could go to a site where someone was like, “Hey, Taylor. Take off this pile of topsoil. Let us know what the cost is for that.” And they helped us do that. Do you guys utilize drones in what you're doing down there as well?

EJ Herron: Oh, yeah, so much that we've actually created a whole new division at our SITECH called CISO Air, and we have a full drone team, and we are like the distributor for DJI Wingtra. We go nationwide, too. So anybody that needs drones, you can contact me. I'll get you hooked up.

Taylor White: That's wild.

EJ Herron: Yeah. We have several guys that are really experienced with all aspects of drones. The LiDAR, photogrammetry, different softwares, what drone to use for which application. We're helping engineering companies, we're helping law enforcement. They use these drones for reconstructing an accident scene, and they can map that out with a drone. I mean, it's just amazing. But with stockpiles takeoffs, it's really neat how you can fly a site from week to week, especially if you're moving a lot of dirt and then take that information and adjust either like some of your building pads, your ponds, maybe you need to bring in some dirt, but you don't want to. So you work with the engineer to make it work. So all that data is just allowing you to make decisions.

Taylor White: Yeah, and that's another thing that has come so far. I mean, I remember when I first started making some videos like five years ago online with the drone, and from where that drone has come from now to what you can get just down into the size from DJI little Mavic Air, it's pretty insane. It's wild. How did they do it beforehand? Like, before drones, what were people doing for stockpile takeoffs? Like, measuring it with, like, a long tape.

EJ Herron: Well, you could even use your rover if you wanted to. You can measure the base of the pile and then walk it, but somebody physically has to walk it to get those measurements. And then doing a site topo, you could use a rover if you wanted to. A lot of guys would drive it with an ATV or maybe like a mule or something and get some takeoffs. But it's like every 20 ft or every 10 ft, whatever you have it set up as. And then before that, you had surveyors that would walk the site and put it all in their grid books, but they're not getting the exact detail that a drone would, up and down the side of a big, giant hill or a valley. It's hard to get that information.

Taylor White: Yeah, 100%. Is it more larger companies that you're working with or smaller companies or a mix of both?

EJ Herron: Who are using drones?

Taylor White: Who are using technology, who are using GPS?

EJ Herron: Yeah, so it's a mix. I would say probably 90% of the large companies are using some sort of technology, whether it's laser, GPS, a robot, they are using it, and most of them have drones that they're using probably every day out on a specific job site. There's a couple of companies in this area, they're flying two or three sites a day and just bringing that back to the estimators and the engineers so that they can take a look at the progress of the job site. I would say the small customers who use technology are probably just a step ahead of everybody else. And to get them on board, it was a demo just to show them the capabilities of the systems.

I remember one guy, he used a dozer system for the first time, and he told me that he had a couple of weeks built into his estimate to do the grading for a big parking lot, and he actually did it in like, three days. So it was like, I'm buying the system. There's no guesswork now. It's like I didn't even have to get out of the machine and get out of the AC. I could just let the machine do it myself and have the other guy running the roller all day. So small customers, big customers, everybody gets an advantage with using technology.

Taylor White: Yeah, 100%. Yeah, I agree. I would totally agree with that. It's what you said. It's the demo that's super important as well, too. Getting them out and actually seeing it like being someone a business owner that has machinery, seeing it on a small job site or like a new home build or grading or a septic system that's where I think it would really shine for us and help us with okay, let's take the plunge and kind of really do this. Is there a project or something that you really worked on that stands out in your head as far as maybe it was a job site you were on with GPS that is kind of like, holy crap, this is a really cool job site?

EJ Herron: I visited one here recently that had like over 100 machines on it and a majority of the excavators had GPS on them. The dozers had GPS and it was amazing to see because there were no stakes out there on the job. Everybody's digging using the model, so when the excavator is in the cut, they don't have to have a Dozer come up and actually push to them to make sure they're degraded using GPS on the Dozer. The excavator already has that in his cab and they don't have to have a surveyor out there marking or a guy chasing him with a laser. So it's pretty impressive to see something like that.

I was on another small site one time and the contractor was demoing the technology and before we arrived and put it on the machine, he thought he had a back hill that was graded. I can't remember if it was like a 3:1 slope, but he's like, it's perfect, we've done it. I said, “Okay, we'll take your Dozer out there. Now that you have GPS, see if it's on grade, make sure it matches.” And they ended up bringing 20 more truckloads of dirt in to get it finished up. I was like, “Okay. Well, I guess doing it by the seat of your pants by eye isn't going to be good enough. You do need to have this type of system or you need to have a lot of stakes out there to help you and stretch string lines, measure. Don't guess, just use the technology to help you.”

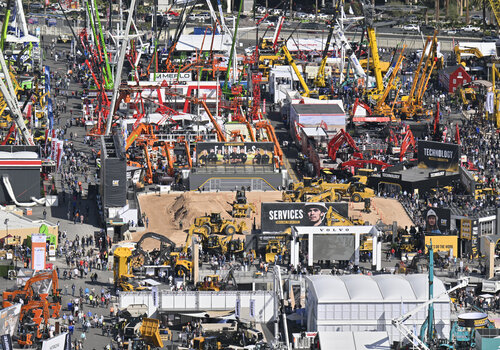

Taylor White: Yeah, I would totally agree with that. There was one thing, there was so much like they had a big technology push and demonstrations at CONEXPO actually this year. And I think actually SITECH was down there, correct?

EJ Herron: Well, multiple SITECHS were, yeah. I went to CONEXPO. I was at the Trimble booth a lot.

Taylor White: How was it?

EJ Herron: Oh, it was impressive. Lots of technology.

Taylor White: Overpowering.

EJ Herron: Oh yeah, so much to see. I always think to myself that I'm going to allow so much time to go visit the different areas at CONEXPO and I run out of time.

Taylor White: Yeah, that happens all the time, frequently. Oh, I'm going to go visit this. We wanted to go see the land clearing booth. That was like the one thing I wanted to really go see and I just didn't even get over there. You get talking to somebody over here and then, okay, you're a little behind schedule and then you're going here. It is quite the show. But yeah, the presence of Trimble and stuff there was really nice to see. I feel like you can see the shift changing, like the booths are getting bigger, the areas are getting bigger for just technology in the industry, which is I mean, you could spend hours.

EJ Herron: And that's what they were talking about. They weren't talking about this machine, that little feature on this excavator or what this widget is on this machine here. But it was about the technology and how they were developing it to work with each machine and what was coming in the future. A lot of mapping, a lot of back end office computer systems that you saw probably to help with planning, help with big takeoffs, tracking your equipment, utilization. Those are big things that we need to look at for the future.

Taylor White: 100%. I'd say that you're definitely the guy to talk to about that. So if people wanted to reach out, what areas do you service?

EJ Herron: So I service North Georgia, mainly Atlanta, Augusta area, Macon.

Taylor White: Nice.

EJ Herron: Yeah, this kind of the central part of the state. We've got actually four salesmen for Georgia, but SITECH South as a whole covers the state of Georgia, Alabama, the panhandle of Florida, and South Florida as well.

Taylor White: Nice. You ever golfed at Augusta?

EJ Herron: No. But I wish I could.

Taylor White: I love Georgia. I drove through it. I was driving to Florida one year, and I just remember them being like, well, it's like the tall pine state. And I just remember there's so many pine trees there. Well, where I was driving, at least.

EJ Herron: Tons of pine trees. Yeah, it's a really great state for all kinds of different things because you have the mountains, you have the city, you have the coast, where you can go to the ocean, and then we won't talk about South Georgia too much. It gets really hot down there and muggy. But it's also right next to Florida, so you do get access to the beaches down there on the Gulf Coast, which is really nice. So a lot of different things you can do within the state.

Taylor White: Yeah. Well, it sounds like it's the place to be, man. So Dig-It Digital GPS so people can go there, find you online, and if you're in the North Georgia area, then they can reach out to you if they got some questions and they want to actually make their business more profitable.

EJ Herron: Oh, yeah, reach out to me if you got any questions, regardless. I have lots of people that send me messages asking about technology and, “Hey, can we do this? Will this system work on this machine? What should I use? Should I use 2D? Should I get it at?” I get those questions daily. So I like helping everybody out. If you got any questions, feel free to reach out.

Taylor White: Yeah. Well, yeah, 100%. I mean, there's 115,000 people that want to see what you're doing, so you're sought after, man. That's for sure.

EJ Herron: Yeah.

Taylor White: Awesome. Well, EJ, I appreciate you coming on today, dude, and talking about everything GPS, and I definitely feel like I know more. I feel like I should probably have a conversation with you and with my local SITECH people now.

EJ Herron: Yeah. Let's get a demo set up, right?

Taylor White: Exactly. I totally agree. Yeah. Thanks for coming on, EJ.

EJ Herron: Yeah, I appreciate it. Always good to hear what you're doing in the industry and what CONEXPO is doing, and appreciate the offer.

Taylor White: All right. Thank you, everybody, for listening to an CONEXPO-CON/AGG Podcast brought to you by our good friends over at Komatsu. We shall catch you on the next one.